During my childhood in Michigan in the 1970s and ’80s, the state was known for two things: the disorienting, tragic, violent decline of its major cities and the manufacturing of automobiles that were somehow getting uglier and less reliable. While I grew up in Ann Arbor—a youthful, optimistic city of 100,000 people built around the enormous University of Michigan—the daily news from nearby Detroit, trips to see my relatives or sporting events, and even the few times when my father brought home a new car all signaled that there was an awful lot wrong with the world around me. Much of society and most of its products felt cheap, flimsy, and easily broken.

I usually tell a short version of the history of Ann Arbor and Detroit when I meet people professionally because the question of how prosperity and calamity could be so proximate shaped my intellectual and professional life. Moreover, my childhood sense that bad cars and bad social outcomes were somehow linked has turned out to be useful to both diagnose problems and generate hope in the face of climate change.

K-car culture

My grandfather was the ideal customer for the Chrysler/Dodge K-car because he could not drive. Owning a car was necessary to participate in life by the 1980s in Michigan, and my grandfather wanted to signal—at least to himself—that, despite illness and deafness, he was still part of life outside the apartment he shared with my grandmother. She leased him a K-car because it was cheap and looked like a car. Indeed, the Dodge Aries K-car looked like a child’s drawing of a car, a box with a couple of diagonal lines and round wheels.

This was not a car that people loved. It was strategically designed to save Chrysler Motors, which was essentially bankrupt after a long period of mismanagement. The idea was to develop a standard, simple platform on which lots of different cars could be made cheaply and sold to people who needed a car, not necessarily ones who wanted this car.

I was the beneficiary of this combination of pride and cheapness, as, after a while, my grandmother determined that my grandfather wouldn’t know if the car left the garage (she drove him in her own car). She gave the K-car to me to drive during my final year of high school. All of a sudden, I could participate in life in ways that were previously impossible. I was grateful for the mobility. Later I became grateful for the lessons about quality this car taught me.

Waste not, sell not

Anyone who rode in my K-car could feel that the vehicle was the result of meetings and budgets, not of inspiration, intention, or care. Its red color and “sporty” two-door style signaled fun and dynamism, but the long, heavy doors were installed imprecisely and opened a bit too wide. If you opened the doors all the way, you faced a dilemma: Endure pained cries from the hinges, or get out of the car to lift and swing the door partly closed before shimmying back in to finish the job. Despite the heaviness of the doors, closing them firmly did not produce a solid sound. Instead, occupants were offered an audible warning that the body of the vehicle was light and rickety.

Perhaps the strongest signal from this car and its Detroit-born brethren was the odometer. Unlike German and Scandinavian cars that had six digits to keep track of miles traveled, Detroit’s cars had five. No one expected these cars to last long enough to travel 100,000 or more miles.

These deficiencies might sound like the growing pains of an industry or compromise solutions to intractable problems, but they were not. They were choices. In the decades leading up to the 1970s and ’80s, Detroit automakers worked hard to turn automobiles, with all of their engineering, steel, and glass, into disposable goods—a business strategy that came to be known as “planned obsolescence.” Alfred Sloan, the CEO of General Motors, championed a version of planned obsolescence that emphasized selling: Make a car that people would want to buy, not to own for a long time. Chrysler, GM, and Ford hoped that the cars they made would go from being featured in the showroom to crushed at the junkyard in just a few years. Someone else’s trash problem was the auto companies’ financial treasure.

Metal madness

I went to college with the belief that if I helped make better cars, a better society would be more likely. I chose industrial engineering (IE) as my major, the study of systems, processes, and quality. I learned physics, calculus, and linear algebra, but I also learned to plan a useful, efficient kitchen, how to measure and avoid waste, and how to think about inventory and raw materials. The discipline taught me to ask questions like, “What is this facility trying to achieve?” “How would I measure success?” “How could one arrange people and machines to work together to produce the desired outcome?” “How would you investigate a process and suggest improvements?” The tools I learned felt basic, like using grammar to write a paragraph or making a list before going to the grocery store. We may have been learning some new techniques, but the principle of considering all of the inputs and processes when trying to do something well seemed banal. Indeed, students in other engineering disciplines derisively called IE “imaginary engineering.” Few of us could have imagined the madness out in the manufacturing world.

The first factory I ever visited was a US Steel plant on the shores of Lake Michigan between Gary, Indiana, and Chicago. It was 1989, and the manager of the plant had invited students from my class to come act as consultants.

We toured the factory, following the path of the materials. Coal and iron ore poured in and got blasted into a blazing river of carbon and iron (that’s what steel is), pushing waves of intense heat throughout the cavernous factory. The liquid steel was then treated to meet the needs of the customer (e.g., combined with nickel, chromium, and other materials to make one grade of stainless steel or another), cooled with water from the lake, and rolled into coils that weighed around 10 to 15 tons. The process felt antiquated, hot, noisy, and dirty, but I didn’t immediately see anything that could be improved—until we got to the end of the line.

Finished steel coils were placed in a huge hall that was open on the sides. The plant manager explained that coils were labeled by hand with a white waxy pencil to indicate the customer and specific product. And then he gestured outside, across a wide expanse the size of many, many football fields, and said, “And here is our problem.”

The area underneath the awning shielded perhaps a few dozen coils from the worst of the coastal Midwestern elements, but if finished product didn’t get sent off to customers right away, workers moved coils into the yard we were now looking at. Before long, not only would the material start to change with exposure to moisture and acidic rain, but the white chalky writing on the coil would grow illegible, so US Steel no longer knew what was what. We walked out into this bizarre landscape littered with dozens, or perhaps hundreds, of coils in various stages of decay. It was like a steampunk nightmare inspired by a Midwestern farm after hay had been cut and rolled into bales.

“What do you do with coils when you don’t know what they are?” someone asked. The guide pointed to the shoreline and explained that the huge crane parked there was used to launch the spoiled coils into Lake Michigan. He seemed sheepish that ancient minerals and deposits of once-vibrant living material had been so egregiously wasted.

Non-cooperation

The following summer, I was very lucky to get a job at Ford Motor Company as a junior quality control engineer. I came to my first day on the job having freshly learned about the Japanese process known as kaizen, which can be understood as “good change” or continuous improvement. In essence, kaizen empowered workers to speak up and work together whenever they observed something that wasn’t right or had an idea for improvement. My new boss told me that I would be working in the Atlanta factory where the Ford Taurus was assembled. This was the big time. The solid-looking Taurus was the best-selling car in America at the time.

Before I went down to Atlanta, my boss explained to me that cars are assembled from the bottom up and the back forward, so the grill and headlamps are the last pieces attached. He then told me about the problem he was trying to solve: In Ford’s American factories, aberrations and deviations accumulated over the fabrication and assembly process, so the grill and lamps never fit. Ford had paid a large sum to build a machine that would bend, twist, and jam the grill and headlamps into place, after which the headlamps had to be adjusted further so that they actually pointed at the road ahead. He showed me a Polaroid photo of the machine. He then showed me a Polaroid of a machine that looked like a gate in a parking garage. Ford had recently paid the Japanese company Mazda to build and operate a plant in Mexico, he explained, and in the Japanese plant staffed with Mexican workers, the grill and headlamps were installed with this simple machine because they easily snapped into place every time.

When I got to Atlanta, I found out that Ford’s approach to their glaring quality problem was decidedly not kaizen: They put engineers and laser measuring devices at the end of the assembly line in hopes of deducing from finished cars which among the myriad parts, rivets, and welds were causing the Ford Taurus to go askew. After a week or so, I was baffled. The odds were low that there was just one “problem” to be “solved.” Furthermore, the workers in the plant, who almost certainly saw inconsistencies and flaws, were not included in Ford’s approach to “quality control.” I suggested that I could walk down the line and ask the workers what they saw. My boss simply said to me, “We don’t talk to them. That’s why we hired you.”

Truth vs. accounting

About 15 years later, in my capacity overseeing research at a large investment firm, I met a veteran management consultant who told me that he had worked with all of the major auto manufacturers around the world during his career. I asked him why he thought Ford, GM, and Chrysler cared so much less about quality than the Japanese and Germans did. His reply was so clarifying that I was shocked to have never heard or thought of it before: “From the 1960s on, the CEOs of the American car companies almost all came from finance, while the CEOs of the Japanese and German companies were engineers.”

An engineer strives to build something that will meet a purpose. When examining a finished product, they ask how it compares to what their team intended to build. If the result and the intentions don’t match, they investigate how to improve the results, how to do so more consistently, how to do so more efficiently, et cetera. Even if it does match, they ask how it could be better.

In contrast, finance deals in symbols and abstractions. Any physical product is purely instrumental to a monetary goal. Value is what someone will pay. At its perverse extreme, business education trains people to create demand through marketing, adjust reality through accounting, and pay for it with cleverly sourced money. In essence, when examining a car, the engineer asks: “Is it good?” and “Is it right?” For decades, American auto executives asked: “Whom can we convince to buy it, and for how much?”

John Maynard Keynes was a marvelous thinker who comfortably moved between economics, art, finance, politics, and other facets of culture. In The General Theory of Employment, Interest, and Money, he analogized investment strategy with a peculiar beauty contest. Imagine a set of photos of models in a newspaper. To win the contest, readers must make a difficult choice:

“It is not a case of choosing those [faces] that, to the best of one’s judgment, are really the prettiest, nor even those that average opinion genuinely thinks the prettiest. We have reached the third degree where we devote our intelligences to anticipating what average opinion expects the average opinion to be. And there are some, I believe, who practice the fourth, fifth and higher degrees.” (John Maynard Keynes, The General Theory of Employment, Interest, and Money, 1936)

In other words, successful investors don’t primarily use their judgment of what is either true or aesthetically good, but rather try to guess what other people are going to guess that other people will guess. From this background, it is easier to imagine how a car company CEO could come to care very little about cars.

For decades, Ford, GM, and Chrysler put more effort into building credit businesses to entice buyers with loans, funding big marketing campaigns, and lobbying governments for favorable tax breaks and regulations than they put into improving their vehicles. The result was hundreds of millions of mediocre cars that lost their value quickly and wound up in junkyards, while their Japanese and German counterparts’ odometers kept on turning.

Culture is a powerful technology

I contend that US Steel and all three of the major US auto companies were culturally bankrupt in the 1980s. It’s not that bad people worked at the companies, but the corporate values, systems, and assumptions made them collectively do bad work. It was a tragedy: Each individual decision made sense, but the end result was madness. Eventually, these firms all went legally bankrupt or nearly so. All were bailed out by the US government at least once, largely for the reasons that were obvious for decades to people who looked at the waste they produced. But institutions can change, and Ford and General Motors are changing.

I participated in a conference at Harvard Business School this May. One panel included Kristin Siemen, the new chief sustainability officer at GM. Siemen stated that GM had been “making electric vehicles for 25 years.” In fact, GM made electric cars for a couple of years in the 1990s, then not only took them all back (GM had leased the vehicles to retain control) but had them crushed. Then GM aggressively lobbied the state of California and the US government to roll back fuel-efficiency standards. One of the main reasons GM feared the electric car was that electric motors are so reliable and long-lasting.

I was encouraged, however, to learn that Siemen is an engineer and—although she used the term “ecosystem” only in reference to GM’s supply chain—her description of how GM was addressing the wastefulness of its vehicles was encouraging. She talked not about technology, but about relationships: setting goals in the C-suite, training employees throughout the firm, getting suppliers together for biweekly meetings, and connecting design and manufacturing throughout the process. She told the audience that all of these were new practices. She then explained that by having more communication throughout the system, GM had discovered that it could actually get to zero emissions first in five, then 10, then 15 years earlier than the company had initially estimated.

I share industrial stories and economic history in these letters partly because they explain how we got to the position we’re in, both socially and ecologically. More important, however, they illustrate that much of the waste and destruction that has led to both climate change and biodiversity loss are the result of cultural practices that require people to look away from obvious perversity. Helpfully, I find in these stories not merely accounts of industrial madness but also the essential ingredients for positive cultural change in the relationships, institutions, and technologies already at our disposal. In 1980, Ford’s premier car, the Thunderbird, looked a lot like the K-car. Ford’s then CEO is famous for asking Ford’s head of design if he would want one in his own driveway. The answer was no. We can make cars—and a world—we are proud to live in.

Crushing it: innovations, breakthroughs, and solutions

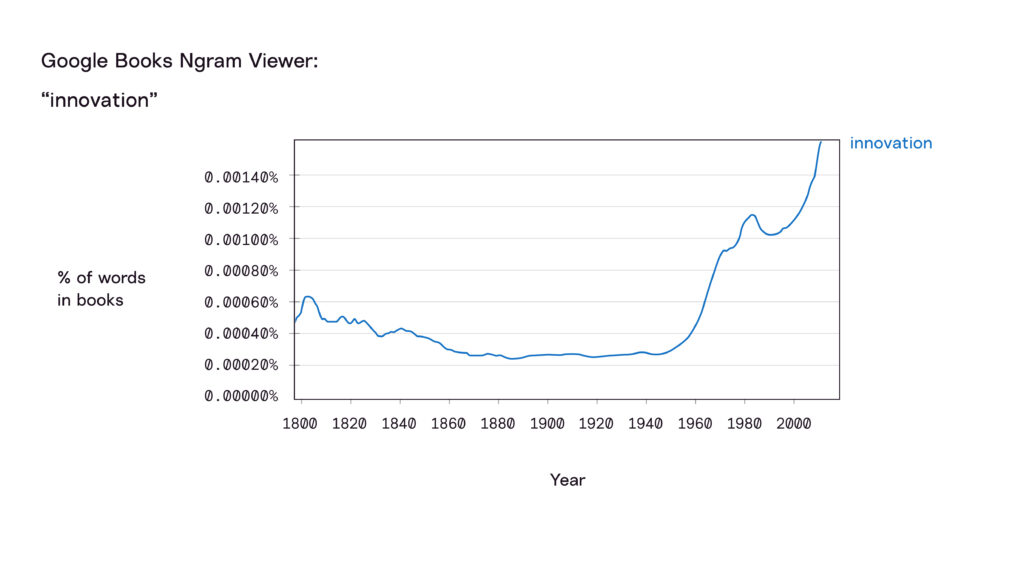

I am glad the business community has begun paying attention to climate change and finding ways to ameliorate the crisis profitably. I am involved to a varying extent in initiatives at a number of institutions, all of which have hosted conferences and events. These gatherings are important because the cultures, frameworks, and language of living with climate change are being established in fora like this. For example, I recently spoke at the Harvard Business School event and one at MIT’s Sloan School (named for the late GM CEO). The two most common words used by speakers—and the unifying idea of the conferences—were “solutions” and “innovations,” both of which are popular business terms. Here is the use of “innovation” in American books between 1800 and 2019:

Virtually every climate business conference invites someone from Breakthrough Energy Ventures, the venture capital fund founded by Bill Gates. The implicit and explicit proposition of Breakthrough is that big, new ideas (and exceptionally high-investment returns) will solve climate change. This is a sexy pitch to the investors who thrived in the past 40 years. Implicitly, if a few super-smart tech people “innovate breakthrough solutions,” there will be a short, profitable period of time during which climate change will be solved, followed by a future of infinite power and prosperity.

I wish Breakthrough were called something like Potentially Helpful Energy Ventures. There can be no doubt that the world needs some good, new ideas for reducing and eliminating the waste we are pumping into the atmosphere. But no matter how innovative they are, we need to collaborate to address climate change, and we should try to break as few things as possible. Society already appears increasingly precarious, and our carbon emissions will again pass historic highs in 2023. As temperatures continue to rise, the integrity of our social, institutional, and physical systems will increasingly determine how well we cope. Moreover, other natural systems are severely damaged or broken, including actual ecosystems and the oceans. I think a clear-eyed, holistic audit can only lead to the conclusion that the natural budget Earth afforded us was lavish, that we are making overdrafts, and that nature’s balance sheet won’t yield to clever accountants or financial analysts (although many will try).

I hope that Probable Futures can help encourage changes in cultures and processes that will enable us to live better now and will prepare our organizations, systems, and societies for the probable futures ahead. I am convinced that climate-aware cultures and processes will not only make infrastructure, societies, and economies more robust but will also make life more participatory, less lonely, and more fun. Very few of us have any chance of innovating new forms of carbon capture or nuclear fusion. Everyone, however, can look around and ask: How could we make society less ugly, flimsy, unreliable, and wasteful? Similarly, everyone can look at maps on the Probable Futures website and ask, “How can I help prepare my home, my family, my friends, my community, and the other systems I engage in for the weather of the present and the future?”

An alternative mindset: resilience, maintenance, and repair

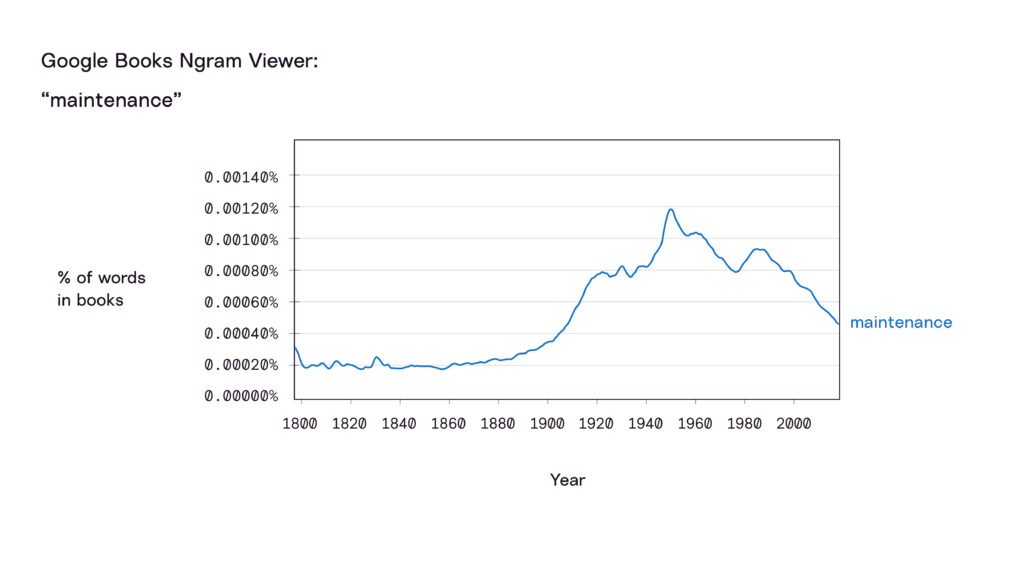

Someone who is succeeding is “crushing it.” Similarly, “disruption” is cool. If wrecking things has become a source of praise, what has fallen out of favor? Maintenance.

Wastefulness may seem like a stereotypical American trait or an obvious symptom of capitalism, but the above graph shows that taking care of things is merely unfashionable, the casualty of a massive cultural change that began in the early 1980s.

Maintenance and inventory management may have never been sexy, but they have usually been among the highest return activities that a company can engage in if sustained. In the late 1980s and early 1990s, though, inventory management got hot in America—thanks to pressure from Japanese competitors, the amazing supply chain and store management of Walmart, advanced information systems (including barcodes), and the fact that it appeared clearly on balance sheets. Not only did higher profits ensue, but falling inventories wound up accounting for roughly half of all US productivity gains over the ’90s.

Now I hope maintenance and repair can become cool. If Americans need motivation, Japan can again offer inspiration.

One of my favorite things about Japan is that maintenance is visible and well designed. People who tend to streets, pipes, wires, gardens, and trains wear good-looking work uniforms, and even service equipment is not only functional but stylish. Consider “Doctor Yellow,” the Japanese train that runs on the country’s high-speed rails to diagnose potential problems:

It turns out that Japan has an entire fleet of specialized maintenance trains that run in the wee hours of the night. Here is an ultra-realistic drawing of one that senses and repairs microabrasions on rails to make rides smoother, quieter, and more efficient (I have a soft spot for a person who considers maintenance trains a worthy subject for meticulous drawing):

Does it work? Well, in 2022, Japan had just five derailments in the entire country, while the US had 1,164.1

Climate maintenance and repair

Society’s spotlights are trained on innovators and financiers, but carrying out even the best conceived and best financed ideas requires lots of other people to meet the intended goals. On a panel on finance and decarbonization at the HBS conference, the moderator asked what financial markets are failing to do. Jayant Sinha, a member of the Indian parliament, eloquently explained the imperative to get money from the rich world to the developing world to help poorer societies adapt, prepare, and mitigate. Scott Jacobs, the CEO of Generate Capital, said that the main problem in the US was different. “In the US, we don’t really need more money. We need more operators.”

Take electric vehicle (EV) charging stations. In the abstract, they are just big plugs, but in a society driving lots of EVs, they’re more like train tracks that can derail travelers. I have heard that charging networks in some countries are reliable, but in the US, somewhere in the neighborhood of 20% of these devices, all of which are quite new, are not functioning at a given time. Some companies raised money based on business plans to sell and install them, but left maintenance to the store or municipality that bought them. Other companies designed, installed, and continue to own their chargers but didn’t plan nearly enough for maintenance.

Maintenance and repair may seem boring to people who want high margins and fast solutions and wear fleece vests indoors, but at the HBS conference in May, we heard from Evette Ellis, the co-founder and chief people officer of a company called ChargerHelp! that offers owners of EV chargers “reliability as a service.” The company takes over the responsibility of keeping chargers in good working order. In doing so, it provides workers with new skills and good jobs while relieving the stress of charging station owners who didn’t anticipate how hard it would be to keep their chargers working (and their customers happy).

Traditional education in the US doesn’t prioritize this kind of training. ChargerHelp! aims to build a new and different workforce, one that Ellis’s co-founder, Kameale Terry, describes as: “You’re OK with getting dirty—and you also understand software and IT.” It’s one of the best mindsets for the future I’ve heard.

We are going to need a smart and physical workforce and a culture of quality, maintenance, and repair, not just for EV charging stations but for the entire dirty, windy, sunny, wet world we inhabit. Mining iron and coal, baking them into steel, and then throwing that steel into a lake is extreme. Still, fundamentally, climate change, the precipitous decline in species, the altering of ocean chemistry, the degradation of soil, and the deterioration of water systems are all a result of the same behavior: exploiting the physical world, generating waste, and failing to repair the damage.

We have broken the systems that gave us climate stability and thereby made civilization possible. Thankfully, there is good reason to believe that among our current institutions and cultures are the resources not only to stop doing damage but to also repair much of what we’ve wrecked.

You have probably heard of companies that will plant a tree to offset carbon emissions. Sounds great, but how many of those companies are investing in people and tools to maintain the forests that are already being counted on companies’ carbon balance sheets? If planting were all it took for a tree to grow to healthy maturity, trees would be ubiquitous. Success will require planting varieties appropriate for the warming world (tip: Consult Probable Futures maps!), helping them through their challenging early years, monitoring their health, and anticipating and responding to threats. It’s a lot more work than just planting, but it could be very good work.

I am excited for people who can look forward to working both indoors and outdoors, approaching climate work with the eye of an honest accountant and the senses of a nature lover. They might work on a boat, turning seawater into bright, reflective summer clouds above Greenland (to slow glacial melt) or the Arctic Ocean (to limit the amount of sunlight that hits the dark ocean that melting ice has exposed). These are examples of the work Sir David King and his colleagues at the Centre for Climate Repair at Cambridge University are piloting.

When I talk with Dave, I’m encouraged. I can easily imagine training programs ranging from weeks to years, both for young people entering the workforce and for those who want to switch from a work culture that lacks kaizen (good, continuous, participatory change) to one that takes systems into account.

Planning for obsolescence (or the zen of motorcycle maintenance)

To get from my college campus to the US Steel plant, my class likely drove past the headquarters of Motorola, a company led by engineers. At that very time, people there were codifying a quality process they called Six Sigma (the name refers to a very low defect rate), based on some of the same principles applied in Japan. Over the ensuing decades, kaizen, Six Sigma, and other quality practices found their way into many US factories, HR departments, and training programs. Today, for example, Ford and GM vehicles are far more reliable and have a sixth digit on their odometers.

GM’s chief executive is now Mary Barra, an electrical engineer. In 2021, she made an important commitment: GM would stop manufacturing any gasoline- or diesel-powered vehicles by 2035. I suspect the company will continue to discover that it can move faster on electric vehicles, but I also suspect it will be culturally difficult to wind down old product lines. The combustion engine is an amazing feat of engineering. If people resist buying or leasing gas-powered cars, however, the finance people at GM will push to make them obsolete.

People often ask me whether they should get an electric vehicle. I reply that my only advice is not to buy a new gas-powered car because it will last a long time and either keep burning fossil fuels or be wastefully destroyed. That leaves them with three choices: Buy an electric vehicle, buy a used combustion engine car, or, probably best of all for now, maintain and repair the car they have until they can afford an electric vehicle they enjoy, as it’s likely to last them a very long time.

Maintaining climate awareness

I founded Probable Futures not because I had a breakthrough innovation, but because I realized that climate science had the potential to be vivid, resonant, and useful. I saw the potential for everyone, everywhere in the world, to develop an awareness of the physical world that would help them in all aspects of their lives and to access climate data that would matter to them.

For a couple of years, I went around asking scientists at different research institutions if making information known by scientists accessible to everyone was feasible. All of them said that it was a good idea but that it wasn’t the kind of thing their organization did. Thankfully, I met two important collaborators at Woodwell Climate Research Center who saw the value of the undertaking: Alison Smart (who would eventually become the executive director of Probable Futures) and Phil Duffy, then president of Woodwell. “It wouldn’t be that hard,” said Phil, when we discussed the idea. He explained scientists wouldn’t build it on their own, however, because the culture of scientific research—and the institutions that traditionally fund it— prioritize novelty and expanding the frontiers of knowledge, not maintaining what is already known.

All of the information that is now on the Probable Futures website was already “public” in the sense that the people and institutions that created the models had saved their output onto databases that anyone could access. In reality, however, accessing that data was difficult, some of the servers weren’t always running, each research institution’s files had idiosyncrasies, and the people who created them are now working on other things. It was harder than Phil anticipated. But we had a good team—led by scientists at Woodwell—to do that work.

The folks who have advised Probable Futures have experience in libraries, transit systems, payment software, and other digital environments that need to be reliable. Our engineers and security experts began building the platform to be robust and capable well before anyone clicked on our website. We are now raising funds so that Probable Futures is reliable for years to come, can be updated thoughtfully, and can fulfill its potential. A few remarkable funders have already supported us, and we are in conversations with others. We are grateful to the many people who continue to help us in myriad ways.

Motown

My collaborators and I have been busy since the March equinox. Probable Futures will soon be available in multiple languages, and we have some exciting new maps and content coming. In addition, we have been speaking and holding workshops at business schools, financial conferences, teacher trainings, and in the halls of government—helping leaders build their climate literacy and hone their skills to assess risk and build resiliency. In just a few days, you might even catch us at the Hollywood Climate Summit, where we’ll be doing the same for leaders in the entertainment industry.

One of the main messages we try to convey is that while technology and infrastructure are important, some of the more powerful ways to increase societal resilience—spending time with neighbors and friends, joining community groups, and helping out with civic projects—can also bring great comfort and joy.

When presenting to young adults, I like to end with the following advice for living well in a changing climate, even when it’s hard and sad: Make friends, learn to cook, dance, and sing. Whatever your age, and whatever the weather brings, I hope you find ways to do all of those things in the season that has just begun. If you’re looking for inspiration, I recommend some Motown. “I Wish It Would Rain,” by The Temptations, might be appropriate.

Onward,

Spencer

Endnote:

1 Train Fatalities, Injuries, and Accidents by Type of Accident

A few recommendations:

The Detroit Industry murals by Diego Rivera in the Detroit Institute of Arts. This one room offers the most comprehensive, vivid, and emotive portrayal of the connection between organizations, people, machines, and nature I have ever seen. It celebrates the potential of industrialization to elevate mankind and warns of its potential to disfigure and destroy.

The film Ford v Ferrari is a fun exploration of the difference in cultures of two auto manufacturers in the postwar era.

Thanks to Jason Kottke for his high-quality, well-maintained blog. I find all kinds of great hypertext products there. He shared the Japanese train pictures a few months ago.

The Death and Life of the Great Lakes by Dan Egan is a fantastic book not just about the history and future of the amazing bodies of water that surround Michigan, but about maintaining an ecosystem in a changing climate. Not throwing industrial waste into the lakes is a good start, but only with true systems thinking will we be able to live well with nature.